Laws of size reduction

- The estimation of the power

requirement of crushing and grinding operations are very important in the

design and selection of size reduction equipment

- But it is not possible to estimate

accurately the power requirement of crushing and grinding to affect the

size reduction of a given material.

- There are a number of

empirical laws to find power requirement crushing and grinding

operations

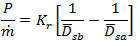

Rittinger's law

It states that the work required for the crushing operation is directly proportional to the newly generated surface area.

- Mathematically

- where

P= power

required by the machine

m = feed rate

to machine

Kr =

Rittinger's constant

Kick's law

- Kick's law related the energy

to the sizes of the feed particles and the product particles

It states that the work required for crushing a given material is proportional to the logarithm of the ratio between the initial and final diameters

- where

KK

= Kick's constant

D and d =

initial and final diameters

- Kick's law is more accurate than

Rittinger's law for the course where the amount of surface produced is

considerably less.

Bond's law

- Bond has proposed a law

intermediate between Rittinger's and kick's law for estimating the power

required for crushing and grinding operations.

Bond postulated that work required to form particles of size Dp from the very large feed is proportional to the square root of the surface-to-volume ratio of the product, Sp/Vp.

- By relation Sp/Vp

= 6/ɸsDp, from which it follows that

- where

Dp =

the particle size

Kb = Bond's

constant that depends on the type of machine and the material being crushed

Hence Bond's law also states that the total work useful in breakage is inversely proportional to the square root of the diameter of the product particles.

- from above equation, a work index

Wi is defined as the gross energy required in kilowatt-hours

per ton of feed material, required to reduce a very large feed to such a

size that 80 % of the product passes a 100-µm screen.

- This definition leads to a

relation between Kb and Wi. If Dp is in

millimeters, P in kilowatts, and ṁ in tons per hour

- If 80% of the feed passes a mesh

size of Dpa millimeters and 80% of the product passes through a

mesh of Dpb millimeters, then from above two equation we get

No comments:

Post a Comment